Polysonic Bullet Treatments

#25100 – Box of 100 – $22.50

#25500 – Box of 500 – $56.25

#25110 – Lot of 1000 – $74.95

#25032 – 1 Quart – $11.95

#25401 – 1 Gallon – $38.95

#25501 – 5 Gallon – $158.95

POLYSONIC FLUID is a new, Environmentally Safe, Water Soluble solution developed by RyDol Products. POLYSONIC FLUID is aneologism for a mixture of high tech components consisting of Hexagonal Boron Nitride (HBN) and PTFE micron particles in colloidal suspension. A one-hour process in a desk-top Ultrasonic tank does the job.

POLYSONIC FLUID is available in Quarts and Gallons. Instructions included.

Polysonic Bullet Treatment

Send us your bullets and we will run them through the Polysonic Bullet Treatment process. We will treat only unopened boxes of 100/500 brand name bullets such as SIERRA, BARNES, BERGER, HORNADY, LAPUA, NOSLER, SPEER, REMINGTON, WINCHESTER, NORMA, etc.

Allow 2 weeks turnaround.

Polysonic equipment recommendations available.

—> Instructions on Polysonic Bullet Treatment <—

EFFECTIVE HBN – PTFE BULLET APPLICATION

March 2011

Competitive shooters started using “Moly Coated” bullets about 10 years ago. Molybdenum Disulfide which is soft flakes of the graphite family. It’s Crap. They roll the bullets in a tumbler with BBs. It’s dirty and fouls; accumulates in the throat of the chamber from excess after 15+shots.

Now the shooting crowd has moved to Hexagonal Boron Nitride (HBN) which is a micron grain platelet of the ceramic family. But they are trying to “roll it on” by using the same method with a tumbler. That’s fine but they are using way too much powder and it does not “stick”.

Over 20 years ago, we discovered that PTFE (Teflon) would electrostatically embed to metal parts (gun parts or any metal) by circulating a floated particle solution in an ultrasound tank for metal gun parts such as slides and bolts as well as bullets. The ultrasound process embeds the particles into the pores (asperities) of the metal but does not put on a “coating” or laminate (which is excess and useless). HBN behaves the same way. Our proprietary mix is a combo of 50/50 HBN-PTFE colloidally suspended in a biodegradable, environmentally safe, non-flammable, non-toxic, non-abrasive, non-corrosive soy methyl ester, water washable solution; resulting in the best products known today in the field of tribology of super slick micron particles embedded in your bullets.

Shooters shy away from our process because a quality desk top Ultra sound tank requires an $800-$1000 investment. A shop parts cleaner or dentist ultrasound box is usually not tuned with the optimum power and frequency requirements but will work to some degree.

So it’s not the size of the bullets, but the time and electricity involved for running a batch.

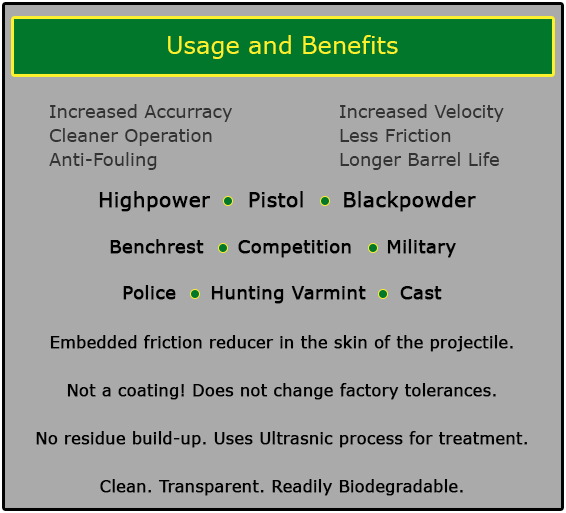

The result is that with the reintroduction of the PTFE/HBN particles in the barrel with each shot, the friction surface becomes smoother and less “pocks” or rough spots will exist for fouling of carbon and/or copper to accumulate. Some immediate things you will notice is that your cleaning brush will meet less resistance in front of the throat of the chamber from the fire flash area build up. Your Feet Per Second (fps) should increase just a tad and the group should tighten because of a more consistent surface for the bullet sliding down the barrel reducing friction variation as you will note in your Standard Deviation (SD) when using a chronograph.

It is a clean operation. Both raw PTFE and HBN powder is white in color and almost transparent when applied. Different qualities of PTFE and HBN are available and the smaller the particle the larger the price tag. We use the smallest of 1 micron or less; the highest quality. And keep in mind how small a micron is.

A little goes a long way.

Dave Fiehtner

U.S. Navy Distinguished Marksman (1975)

Senior Scientist

COO/VP